Custom motorcycle building has always been about more than just mechanical ingenuity—it’s a craft that captures the spirit of adventure, personal expression, and the shared excitement of the open road. For us at Purpose Built Moto, that craft has been our lifeblood from day one. This long-form blog is dedicated to telling the complete story of Project Delta, a milestone build for our workshop that stretched our creativity and skill set in ways we never imagined. It’s a Royal Enfield Super Meteor 650, transformed from a brand-new factory cruiser into a stripped-down, vintage-inspired bobber—complete with a hand-built girder front end, monoshock suspension, and countless little details that tell a larger story of who we are and what we do.

Over the years, we’ve honed our ability to weave both tradition and innovation into every bike we touch. But Project Delta took that ethos to a new level. Named after our own Purpose Built Moto “delta” symbol—which signifies change and forward motion—this machine symbolizes how far we’ve come since our early days in a suburban garage on the Gold Coast. Through each stage of the build, we’ve carefully documented our process in a series of blog posts and videos, but this piece is where it all comes together, from the initial crate arrival to the final test ride and showcases.

So settle in. We’re about to dive into the full, unfiltered tale of how one Super Meteor 650 became a testament to Royal Enfield’s heritage, our workshop’s identity, and the boundless potential of custom motorcycle culture.

One of the most significant aspects of this project was who we partnered with: Royal Enfield. Known for classic-styled motorcycles and a loyal global following, Royal Enfield has been steadily branching out with new models like the Interceptor 650, Continental GT, and the Super Meteor 650. When they approached us to build a one-off custom based on their newest cruiser, we were both thrilled and humbled.

“When we were contacted by Royal Enfield to create a motorcycle based on their Super Meteor 650, I wondered, ‘Why us?’” Tom recalls. “I soon realized it didn’t matter why—the only important thing was, we took this opportunity and ran with it.”

It’s not every day that a major manufacturer hands over a fresh, still-crated bike and says, “Do whatever you want—just let us know when you’re done.” From a creative standpoint, it was an open canvas. But it also came with the responsibility of representing Royal Enfield’s legacy in a respectful yet forward-thinking way. We had to strike a balance between paying homage to their heritage—bikes like the original Meteor and the Flying Flea—and injecting our Purpose Built Moto design DNA, which often leans toward raw, stripped-down simplicity and visceral ride experiences.

Laying the Foundation: Our Approach and Early Ideas

From the start, we outlined a few guiding principles:

- Weight Reduction – Modern bikes can be weighed down by manufacturer requirements and rider expectations for comfort and accessories. We wanted to strip away anything unnecessary, dropping the curb weight dramatically so the rider feels every vibration, every pulse.

- Vintage Aesthetics – Girder forks, a simple bobber seat, and classical design cues are signature elements of 1940s–1950s motorcycles. Blending those details into the Super Meteor 650’s modern frame would give the bike a unique, time-worn appearance—yet it would still be brand-new in performance and reliability.

- Showcasing the Engine – The Super Meteor 650 uses Royal Enfield’s 648cc parallel twin, a versatile powerplant with a 270-degree firing order. It has a bold presence, and we wanted to visually highlight it rather than hide it behind large covers or bodywork.

- Capturing Royal Enfield’s Heritage – We studied the original Super Meteor from the mid-20th century, along with personal favorites like the diminutive yet iconic Flying Flea. Certain lines, silhouettes, and mechanical concepts from these older bikes inspired our build.

“Instead of relying on that personal relationship we usually have with a single client, this time we were relying on the history and brand image of Royal Enfield,” Tom explains. “We looked at their heritage, and tried to intersect it with the style we like to create at Purpose Built Moto.”

By combining these themes with an “oil in frame” approach, custom girder front suspension, and a monoshock rear, we aimed to produce something that was equal parts homage and innovation.

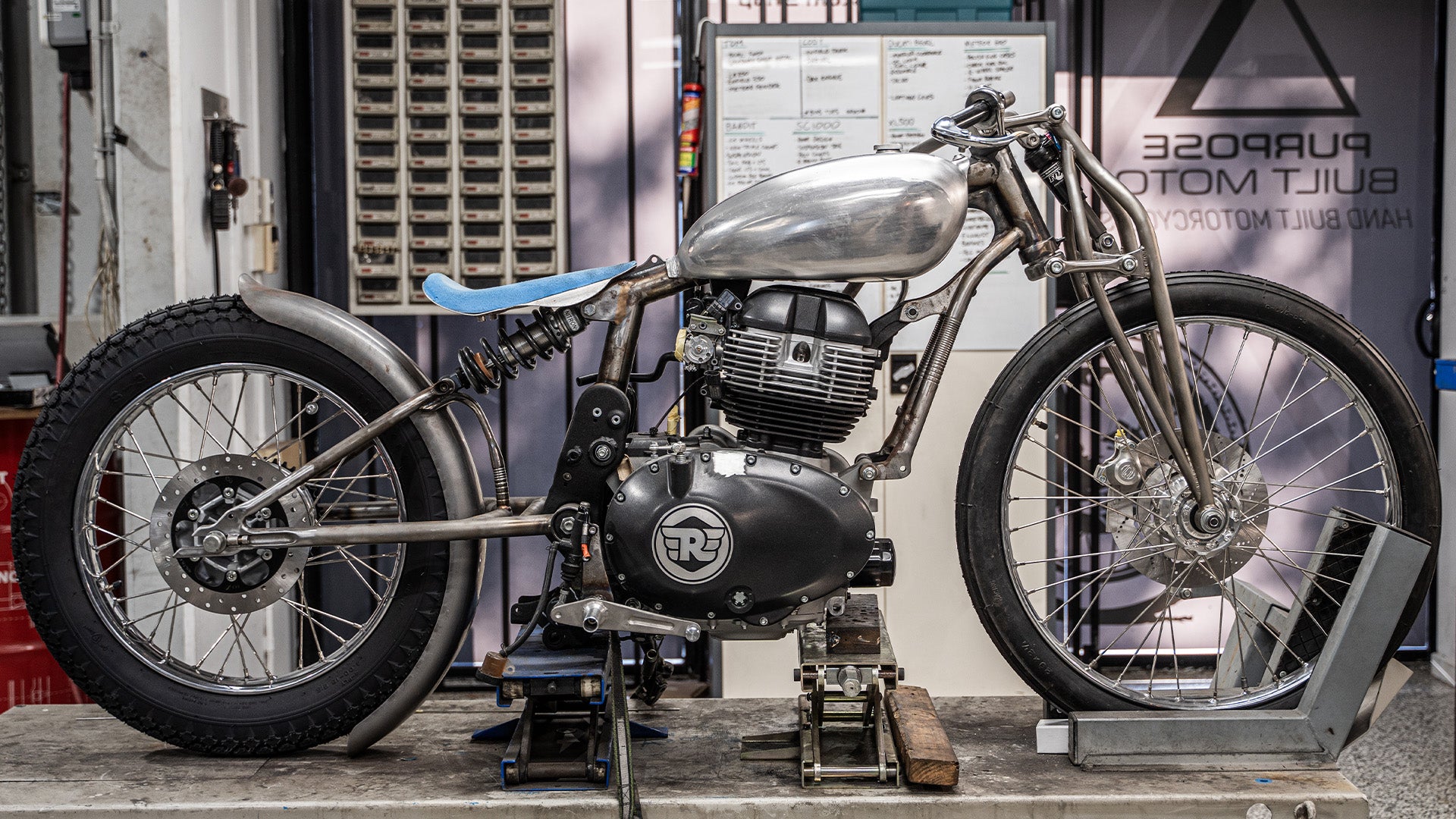

The Teardown: A Brand-New Bike, Already in Pieces

Opening up a crate that contains a factory-fresh motorcycle is a rare treat. Typically, we see well-worn bikes come through our doors, complete with years of patina or mechanical issues. But this time, the paint was immaculate, the seat unmarked, and the motor unrun.

“Super Meteor turned up here in a crate, delivered earlier this year,” Tom says. “First time we’ve been given the opportunity to unbox a bike, so we pulled it out, and it was actually one of my first times seeing the bike in the metal.”

We only gave ourselves a few minutes to soak in the stock form: a 240-kilogram cruiser with comfortable ergonomics, forward controls, and a laid-back vibe. Then the tools came out. Seats, fenders, side panels, the heavy twin-shock mounts—anything that wouldn’t serve our vintage-bobber direction was unbolted or cut away.

The teardown quickly revealed how we might drastically alter the geometry. Royal Enfield’s Super Meteor is designed around comfort and stability, but we wanted something more raw and immediate. Stripping away unwanted pieces also dropped the weight substantially, allowing us to see the engine and bare frame—a blank canvas awaiting our custom touches.

Frame Modifications: From Twin-Shock to Monoshock, Plus Oil in Frame

The heart of any custom build is the frame. After removing the extraneous brackets and subframe loops, we focused on three major tasks:

- Monoshock Conversion – Instead of the traditional twin-shock arrangement, we planned a single shock near the engine pivot. This required designing new swingarm pivots, shock mounts, and re-bracing the frame to handle load forces differently. We chose a custom-built Nitron shock for adjustability and consistent performance.

- Oil in Frame – Looking at vintage bikes from the 1940s and ’50s, you often see simpler cooling solutions. We decided to remove the stock oil cooler and run oil through the frame rails themselves. Was it as efficient as a modern radiator-style oil cooler? Probably not. But it cleared up the front end visually and evoked that old-school aesthetic.

- Slimmed Backbone & Neck – Our custom aluminum tank would sit close to the backbone, so we trimmed away some of the bulky cast sections around the steering neck and thinned the backbone. We then added handmade gussets, creating a strong yet minimalist front frame section.

“When my grinder comes out, I do get a little excited,” Tom jokes. “We have removed a lot of what was there just because the simpler I can make this motorcycle, the better it’s going to be.”

In the end, the original Super Meteor frame was still present in spirit—it held the engine and geometry points—but almost everything around it was rethought to fit our vintage-inspired design.

Designing and Building the Girder Fork

Arguably the centerpiece of Project Delta is its front suspension. Girder forks harken back to the early years of motorcycle development, predating the mainstream telescopic fork. They rely on a system of linkages and pivot points, which can create a unique “floating” feel when riding.

“Creating a girder front end is something that was directly inspired by the Flying Flea,” Tom says. “When those models first came out, they had this really beautiful front end. I wanted to take that, add my own touch to it, and apply it to our new Super Meteor build.”

Key steps involved in building this girder fork:

- CAD and Geometry: Before cutting metal, we mapped out rake, trail, fork length, and shock mounting positions in a simple CAD layout.

- Machining and Fabrication: We cut and milled steel plates for the fork legs, then painstakingly welded them together with cross bracing. A modern downhill air shock replaced the coil or leaf springs of older girders, giving us fine-tunable damping.

- Alignment Checks: Small miscalculations in girder geometry can greatly affect handling. We used a laser to confirm alignment and tested the motion through its entire travel range.

Once assembled, the girder fork gave the bike a distinctive, mechanical look. At rest, you can see every pivot point and bracket—a functional sculpture that sets the tone for the entire build.

Wheels, Seat, and Bobber Styling

A vintage bobber stands out partly because of its wheel choices and seat placement. We selected a 23-inch front wheel and a 19-inch rear to achieve a certain “board track” aesthetic. These were hand-laced rims with specialized hubs—one for a single disc brake up front, and a Continental rear hub out back.

Meanwhile, the seat is a floating single pan, mounted in a way that reveals the shock linkage underneath. Trimmed in a cherry red leather, it contrasts beautifully against the neutral paint scheme. We also used the same leather for grip wraps on the bars and tank shifter, tying everything together visually.

“We want you to feel the motorcycle when you’re riding it,” Tom explains. “That’s why we set up a bobber-style seat with minimal padding—it keeps you closely connected, so you get instant feedback from the machine.”

With the seat and wheels dialed in, the bike’s stance took shape, blending a tall front wheel, minimal rear fender, and the newly slimmed frame to achieve that old-school silhouette we envisioned.

Crafting a Hand-Made Aluminum Tank

If the girder fork is the build’s mechanical centerpiece, the tank is its aesthetic heart. For Project Delta, we wanted a tank that drew inspiration from older Royal Enfield designs—particularly the 1950s Super Meteor—but in a much slimmer form.

Cody, our in-house fabricator, took on the challenge of shaping the aluminum tank. It started with a cardboard template and some initial sketches, then moved to forming aluminum panels by hand. Each side was carefully hammered and planished until the contours matched our design. Once the tank was tack-welded together, we verified fitment, making sure it left enough space to show off the engine.

Fitting the modern fuel pump into the smaller-than-stock tank was tricky. But after some internal bracket fabrication, we successfully merged new technology with classic form. The result is a tank that appears vintage from the outside yet functions seamlessly with the Super Meteor’s fuel-injection system.

The Hand-Shifter: A Nod to the Past

To drive home the retro vibe, we relocated the gearshift to the left side of the tank. Old-school bikes often featured foot clutches and hand shifts, especially in the chopper/bobber scene. We spun that concept into a tank-shift configuration that simultaneously cleans up the handlebar area and introduces a bit of novelty to riding.

We pivoted the shifter arm off the inspection cap on the stator cover, creating a direct linkage to the transmission. The result is a setup that demands a more hands-on approach—literally. While it takes some practice, it’s incredibly rewarding once you get the hang of it.

“Pivoting off the inspection cap on the stator cover, we’ve made the bike a hand-clutch, tank-shift configuration to keep the bars clean and add a bit of custom flair and novelty to the ride,” Tom notes. “We wanted that raw, visceral ride feel. Shifting by hand really immerses you in the bike.”

Exhaust, Intake & Finishing Touches

No custom bike is complete without the right exhaust note. We fabricated a stainless steel fishtail system, bending the headers by hand and integrating internal mufflers to maintain a deep, throaty sound that complements the 270-degree twin’s character. At wide-open throttle, Project Delta howls, but it never crosses the line into obnoxious territory.

“The fishtail style mufflers were something we had in mind from the beginning,” Tom explains. “They echo that art-deco style we used in other areas of the build.”

For intake, we turned to a set of spun-brass velocity stacks—a one-of-a-kind piece made possible by a metalworker Tom met in Athens. These air intakes give the build an additional custom flourish and speak to the global influences that can shape a single motorcycle.

The final details included a PBM Black Box for simplified wiring, Kustom Tech brake and clutch levers, and an art-deco inspired rear fender light that ties the “heritage meets modern” theme together.

Paint and Aesthetic Cohesion

Our paint design needed to be simple, refined, and in line with the era that inspired us. We chose a base color that wouldn’t overpower the mechanical artistry, adding subtle gold-leaf filigree and cherry-red pinstriping (matching the seat leather). The tank wears a heritage Royal Enfield logo and the Purpose Built Moto signature, placed carefully to balance branding and minimalism.

“Our paint design needed to be simple, letting the fabrication and design work do the talking and letting the shape of the bike shine,” Tom says. “We’ve sketched out a design that included some filigree detailing to be done in Gold Leaf and pinstriped with a matching cherry red from the seat leather.”

Justin from Popbang Classics executed the paintwork, layering multiple coats and finishing them with a high-quality clear. He pinstriped the lines by hand, working off our sketches to incorporate curves that harmonize with the bike’s geometry. Once all the painted pieces were done, we meticulously reassembled the entire machine, double-checking torque specs and alignment before it saw daylight again.

Tom’s Reflections: Constant Evolution at Purpose Built Moto

For Tom, the significance of Project Delta isn’t just about a singular build—it’s about the evolution of Purpose Built Moto. Anyone who’s followed our workshop knows that we started small, with minimal tools and a ton of enthusiasm. Over the years, we’ve built a reputation by tackling increasingly complex and ambitious projects. This Royal Enfield commission allowed us to push ourselves further than ever.

“I never want our newest bike to be the same as the previous one,” Tom points out. “Everything that we build, I strive to make just that little bit better, whether it be a different design direction, better fabrication, more creative ideas—the way that we style our machines, the paint design. I always am looking for areas we can level up.”

That drive for progress is symbolized by our shop logo, an offset triangle representing the Greek letter delta—a value of constant change. With Project Delta bearing the same name, we put that philosophy front and center. The bike embodies our growth, from a small garage operation to a workshop building commissioned customs for major manufacturers.

The Test Ride: Where Theory Meets Reality

No build is complete until it’s tested on the road. We don’t believe in trailer queens—our bikes are made to be ridden hard and enjoyed fully. That’s why the first real test ride is always a pivotal moment. For Project Delta, it meant rolling out of the shop, feeling the significantly reduced weight (down from about 240 kg to roughly 157 kg) and hearing that parallel twin bark through the fish-tail exhaust.

“We don’t build motorcycles to be put on a shelf or to be put in a showroom,” Tom says. “We build them to be enjoyed.”

Almost immediately, you sense how the lighter frame transforms the power-to-weight ratio. The 270-degree twin feels punchy off the line, the hand-shift adds an element of rider engagement, and the girder fork provides a unique steering feedback that’s both nostalgic and surprisingly stable. Meanwhile, the monoshock in the rear soaks up road imperfections but still transmits enough feedback to remind you that you’re on a custom machine—built to connect the rider to the road, not isolate them from it.

“Winding it through the hills, watching the girder suspension work, feeling the mono shock and the new swingarm we’ve built operate underneath you—that’s the symphony of mechanical parts finally talking to each other and delivering that ride experience,” Tom explains.

Every custom build has its share of last-minute tweaks. After the test ride, we tightened a bolt or two, adjusted the shock preload, and changed the angle on the hand-shifter for a smoother motion. But overall, Project Delta performed beyond our expectations, proving that form and function can intersect when carefully planned.

Detailed Specs

Here’s a rundown of the core specs and custom modifications that define Project Delta:

Base Motorcycle: Royal Enfield Super Meteor 650

Engine: 648cc, 270-degree parallel twin (approx. 47 hp / 52 Nm stock); fitted with metal-spun brass velocity stacks, upgraded fueling via Dynojet Power Commander

Weight Reduction: Down from ~240 kg to ~157 kg curb weight

Frame: Modified Super Meteor chassis with monoshock conversion; oil-in-frame concept for radiator-free cooling aesthetics; slimmed backbone and custom gussets

Front Suspension: Hand-built girder fork using an adjustable downhill air shock, designed with CAD and manual machining

Rear Suspension: Custom swingarm with Nitron monoshock

Wheels: 23-inch front, 19-inch rear, hand-laced rims with single-disc hub up front; vintage-pattern tires

Tank: Hand-built aluminum tank inspired by 1950s Royal Enfield shapes; internally mounted modern fuel pump

Seat: Floating bobber-style seat pan trimmed in cherry red leather, matching leather grips and tank-shifter handle

Hand-Shifter: Tank-mounted shifter with hand-clutch conversion; Kustom Tech lever assemblies

Exhaust: Custom stainless steel headers and fishtail mufflers with internal baffles, welded in-house

Wiring/Electronics: PBM Black Box for simplified wiring; minimal bar switches and hidden routing; Deco tail light from PBM

Paint: Base color with gold-leaf pinstriping, cherry red highlights, and vintage Royal Enfield insignia; completed by Popbang Classics

Finishing Details: Machined stainless brackets, custom fender struts, oil lines through frame rails, and hidden battery/electronics under the seat

Project Delta: A Statement, Not Just a Bike

Throughout this build, our mantra remained consistent: custom motorcycles are more than a collection of parts. They’re rolling expressions of heritage, creativity, and the unbreakable bond between a rider and their machine. When we look at Project Delta, we see the sum total of thousands of decisions—each one adding a layer of authenticity to the final product.

“Naming the bike Delta and being representative of change also represents a change we’ve undergone at Purpose Built Moto,” Tom says. “We’ve come from a one-man band in a tiny garage in my home to where we are today.”

That journey reflects in every weld bead, every swirl in the brushed aluminum, and every time we shift gears by hand. It’s a powerful reminder that the passion fueling us in our early days is still here, stronger than ever, now amplified by more advanced fabrication skills and bigger creative visions.

The Ride Goes On

Perhaps the most exciting part of Project Delta’s story is that it doesn’t end when we set down our tools. As a fully functional bobber, it’s ready to hit the highways, back roads, or show floors—wherever it can best spark conversation and show how deeply custom culture runs in modern motorcycling. The fact that Royal Enfield themselves supported this project speaks volumes about their commitment to fostering a global custom community. It also showcases how a modern 650 twin can be utterly transformed without losing its core identity.

“With the weight that was thrown behind this project, I wanted to make sure that we represented ourselves in the best possible light,” Tom reflects. “We aimed to create something that felt raw and vintage-inspired but still carried the reliability and performance of a modern machine.”

At Purpose Built Moto, we’re already looking forward to future builds. Project Delta served as a catalyst—showing us the heights we can reach when we push our limits, from designing a girder fork and monoshock rear to perfecting a hand shift that merges novelty with functionality. In many ways, it’s a blueprint for what’s possible in the intersection of old and new.

Conclusion

Project Delta stands as a major milestone for Purpose Built Moto—a statement piece that merges Royal Enfield’s storied heritage with our constant push for evolution and reimagination. From the moment the Super Meteor 650 arrived in a crate to the final test ride that saw it roaring down the Gold Coast, the build has embodied the spirit of motorcycling’s past, present, and future. Every bracket, weld, leather stitch, and pinstripe was crafted with intent, culminating in a bike that’s as show-stopping as it is road-ready.

We hope that by sharing the complete story—the challenges, the inspirations, the behind-the-scenes processes—you’ve gained a deeper understanding of what custom motorcycle building means to us. It’s about community, shared passion, and the pursuit of that feeling you get when you open up the throttle on a machine you’ve poured your heart into. As we often say, “We don’t build motorcycles to be put on a shelf. We build them to be enjoyed.”

Royal Enfield took a chance by entrusting us with this project, and we couldn’t be more grateful. Project Delta reflects the best of two worlds: their timeless ethos of riding pure, classic bikes, and our relentless drive to break new ground in design and fabrication. It’s a marriage of heritage and innovation that, in our view, captures the essence of what makes custom motorcycling so special.

Whether you’re a dedicated fan of Royal Enfield, a fellow builder, or just someone who appreciates meticulous craftsmanship, we hope Project Delta resonates with you. This one-of-a-kind machine serves as a rolling reminder that the potential for creativity in the motorcycle world is limitless—so long as you’re willing to pick up a grinder, sketch out a design, and chase the thrill of turning a bold idea into rubber, steel, and fuel.

Ride safe, stay curious, and keep pushing your own boundaries—on the road, in the garage, and everywhere else in life.

WE BUILD BIKES WITH PURPOSE.

Purpose Built Moto is home for unique custom motorcycle builds. We offer a unique motorcycle customizing experience in the heart of the Gold Coast.

1 commentaire

What a beautiful classy build. Your work is suppurb. I loved the front forks, the gear/hand shifter, the handlebars and the overall shine and perfection.