What does it take to build an electric motorcycle

It’s been a while since we’ve run a guest builder blog so I thought I’d change things up a little for this one. Until now we’ve featured some really valuable how-to content from builders with a lot of old world skill. This time we’re pushing a little further into the future to talk with Dennis Savic, a Australian young designer-entrepreneur from Melbourne who’s been working on a high-performance electric motorcycle.

Savic Motorcycles has been gaining momentum of late and I’ve been talking with Dennis more regularly to throw ideas around, which has been great. It’s nice to find someone as driven and hardworking as we are at PBM.

This guest blog we’re going to take a look inside Savic Motorcycles, and figure out what they’ve been up to and just how they’ve landed on their current production electric moto design.

Before Savic, did you have any experience working on motorcycles?

A little. My first encounter with motorcycles was hanging out with a friend who rode bikes. He actually wound up teaching me to ride in the basement garage of his apartment building.

From the word go, the engineer in me wanted to start pulling the motorbike apart to see how it worked. My first bike was his too, a 1996 CBR250RR. I wish I still had it; it had a phenomenal rev range.

I bought the bike to help me with my university project, which ended up being my first taste of reverse engineering. Since then, I’ve literally pulled apart every bike I’ve ever owned.

What drew you towards developing an e-bike?

I love the technology, and also of course, the design freedom that you get from starting from the ground up.

If you’re using an existing power plant (like an engine out of another bike), you’ll always be limited to that engine and building the bike from there. Part of the reason why I’m a huge fan of the Britten is that the dude literally cast his own engine.

So I’ve been thinking about e-motorcycles for the better part of 10 years.

How long have you been developing this bike, and how far away are you from a production model?

The C-Series has had three iterations over the past three years, but I’ve been working on developing a production bike for the better part of five years.

The first year was spent thinking we were going to build a 200kw monster, but then I learned about what it means to have a viable business case and knowing the market in which you play.

So when we built our first ground-up bike in 2016, that was a huge learning curve, and we realised we’d have to go back to the drawing-board and start over again.

What sets Savic Motorcycles apart technically? Why would someone buy one of your bikes over any other brand?

We’re going to have some ground-breaking software smarts that we haven’t announced yet, which will be fun for the customer but also bring them closer to the bike than they’ve been able to get before.

When it comes to performance, our bikes will be on par – or hopefully even slightly better – than the Livewire or the Zero.

The technology in our bike is all our own (ie. we’ve designed our own battery packs and motor etc.), however the laws of physics and business only allow us to do so much with the technology that’s currently available. We’re not going to start developing new cell technology for motorcycles just yet!

What we are doing, however, is finding some of the best components from suppliers all over the world, and bringing them together in a stunning high-performance package, while making our bikes some of the most affordable e-motorcycles on the market.

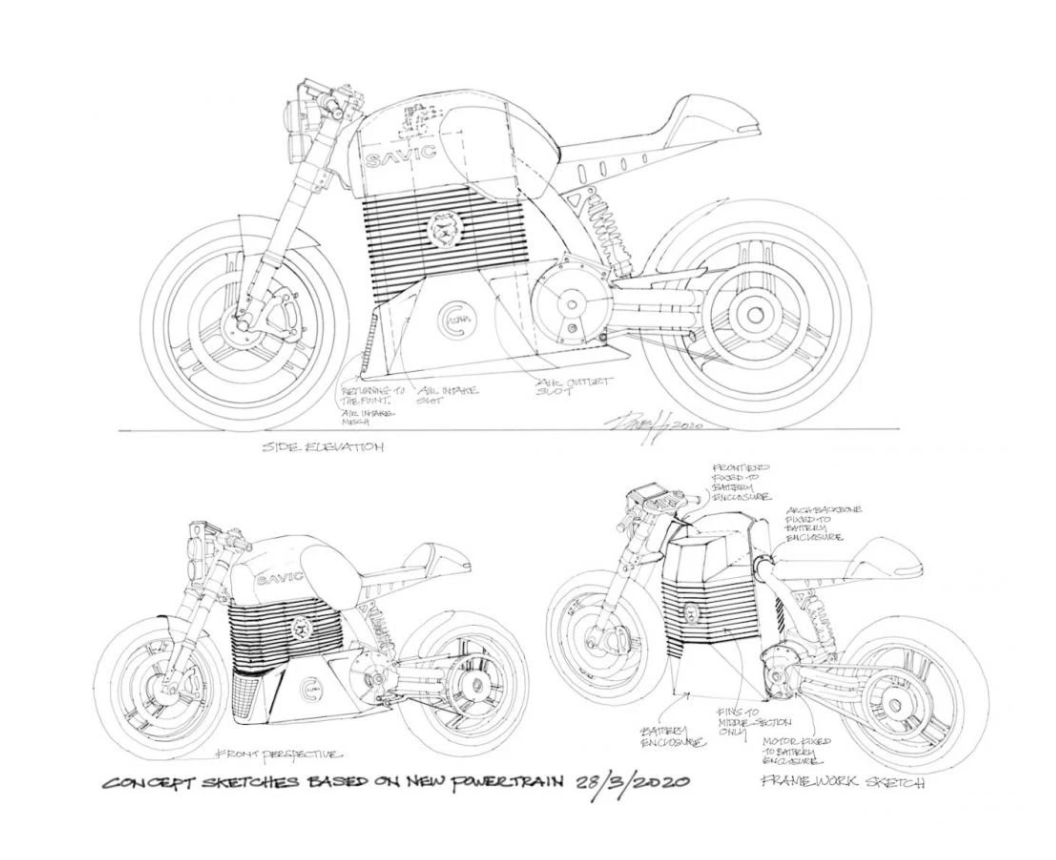

Where did the design process start, ie. Did you have a rolling chassis and design around that or take a different route?

We literally started with a blank sheet of paper. In this company, we all suffer from some degree of designer syndrome – we want to create something new, something that’s ours.

On the 2020 bike, we even designed and engineered our own axles and axle nuts!

What have been your biggest challenges in getting this idea off the ground?Developing a motorcycle for production is hard. And getting a motorcycle design into production is a whole new level of hard. Making it a designer motorcycle while still maintaining a viable business case – well, that’s not easy either.

But the team are all powering through. They’re all so passionate and talented. They make some of the hardest challenges we’ve had seem simple.

Through these challenges what’s been pulling you through?

For me personally? This is something I’ve wanted to do since I was a kid.

I’ve dedicated my life so far to the pursuit of building an automotive business. The reason why I chose to do a Bachelor of Mechanical Engineering was to learn the technical side and complement the hundreds of hours I’ve spent pulling apart and reassembling bikes. I did my MBA so that I could understand the concepts and language of the business world. Back in 2016 I sold a car which I’d worked incredibly hard for to buy bike parts. I’ve had weeks with so little cash that I lived off spaghetti and tomato sauce. A diet that I wouldn’t recommend, by the way!

What’s really pulled me through, though, are the team and the passion and talent they all have. They’re honestly amazing. It sounds so cliché, but I genuinely feel privileged to work with all the people in our team.

What’s the driver behind the sports bike crossover style of your bike?

Well, the C-Series is a modern rendition of the café racer. So we wanted to modernise and tweak the definition of what a café racer was.

From the outset, what did you want to achieve in the way this motorcycle looked? What’s the design DNA?

The design scope was simple: timeless, unique, and simple. We wanted to start with a café racer because we love them. We liked the backbone direction and that will be one key to our design DNA going forward.

We also asked the designer to consider production. At the end of the day, we want to produce many of these bikes, not just a handful, so we needed a design that was simple enough that it could be manufactured affordably. The simple design also hints towards elegance, and a clean aesthetic.

What do you think the most important thing has been to get your company to this point?

Persistence – and not quitting when things appear to be impossible. If one can logically deduce that an outcome is not impossible to achieve, as improbable as that may be, then why quit? People normally say things are impossible if they can’t see a way to get there, but this is not correct. It’s all about figuring out how to do it. If there’s a will, there’s always a way.

I could talk to Dennis all day about this stuff, the enthusiasm really shines through. Make sure you go over to Savicmotorcycles.com and sign up for their newsletter to keep an eye on what they’re up to. I personally have much more of an understanding about this emerging Australian company in the Electric motorcycle space, so I’m sure you do too. I hope you enjoyed the change of pace on our guest builder series, and if you have any more questions for Dennis, leave us a comment below and we will get him to answer them.

If you are wanting to get build your very own Australian electric motorcycle get in touch with us!

WE BUILD BIKES WITH PURPOSE.

Purpose Built Moto is home for unique custom motorcycle builds. We offer a unique motorcycle customizing experience in the heart of the Gold Coast.