We’ve broken down the different steps, parts of your engine and possibilities to help you figure out a motorcycle engine rebuild cost

Right off the bat let me say that the question ‘how much does a motorcycle engine rebuild cost? is loaded with a lot of complexity within the answer. We’ve taken the time to answer this question thoroughly so this article is going to be a long one.

There are a lot of variables that affect the motorcycle engine rebuild cost. What I’ll try to do here is break down the basics of what you’ll be paying for when it comes to having your motorcycle motor rebuilt.

If you want to skip the light reading and just have your bikes motor rebuilt better than new, get in touch with us here to have it done

The Questions we will try to answer for you are:

- What are the different costs involved with an engine rebuild?

- What are the variables that can make the rebuild cost more or less?

- How much are engine rebuilds through Purpose Built Moto? Broken down into engine types

- What are a few ways to lower the cost of your bike’s engine rebuild?

- What are some cost effective upgrades that can be done during a rebuild?

Before you go ahead and price a rebuild you need to ask yourself, does it need to be done? If you’re not sure about your motorcycle engine’s condition read this:

9 Signs You Need An Engine Rebuild

As always when it comes to pricing, we have to talk in general terms, from past experience. Each engine may be a little different in terms of what needs to be replaced or repaired. So let’s get into some details about having your motorcycle engine rebuilt.

What are the different costs involved with an engine rebuild?

By far the most expensive part of an engine rebuild is the parts needed. The condition of your engine can affect this part of the cost hugely. For example if we pull an engine down and find most of it in really good condition with only the consumables needing to be replaced, that’s your ideal situation.

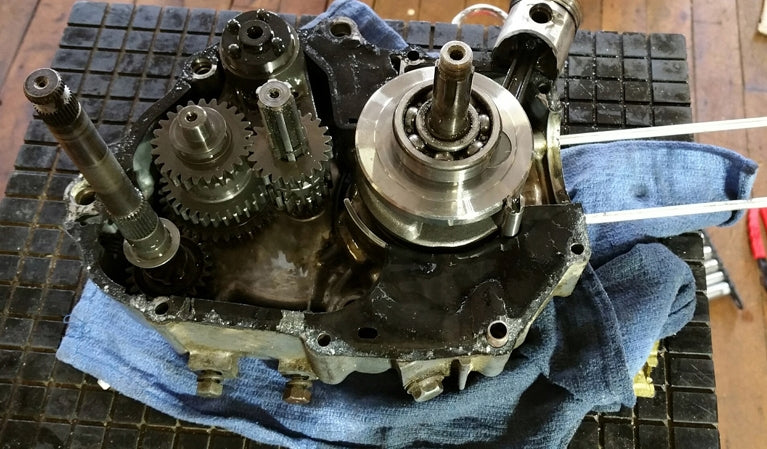

However, if we pull a bike motor apart and find damaged gearbox components, heavy damage to the head, barrels or crank cases this can quickly blow your cost out. The bad part about this is that by the time you figure it out the engine is in pieces, and you’re past the point of no return.

The engine type also greatly affects the cost of your build. The amount of parts needed to rebuild a 16 valve, 4 Cylinder motorcycle is more than 4 times that of a 2-valve-single-cylinder motorcycle.

The costs involved in your engine rebuild are as follows:

Gaskets + Oil Seals : $50-200

Top end parts: pistons, rings, valves, valve springs, cam chain or pushrod parts, Cams if needed etc. – Cost dependant on engine type and condition discussed further below

Bottom end parts: Bearings, bushings, replacement of any damaged gearbox parts, clutch parts, stator/rotor parts.

– Cost dependant on engine type and condition discussed further below

Machining: This can include top and bottom end parts, repairing bearing or cam races if damaged. We will generally at a minimum have the Barrel honed to suit the new piston, valve and valve seats re-surfaced for fit. You can also request porting work on your head for better intake and exhaust flow. $400-1500 depending on what’s needed and engine type.

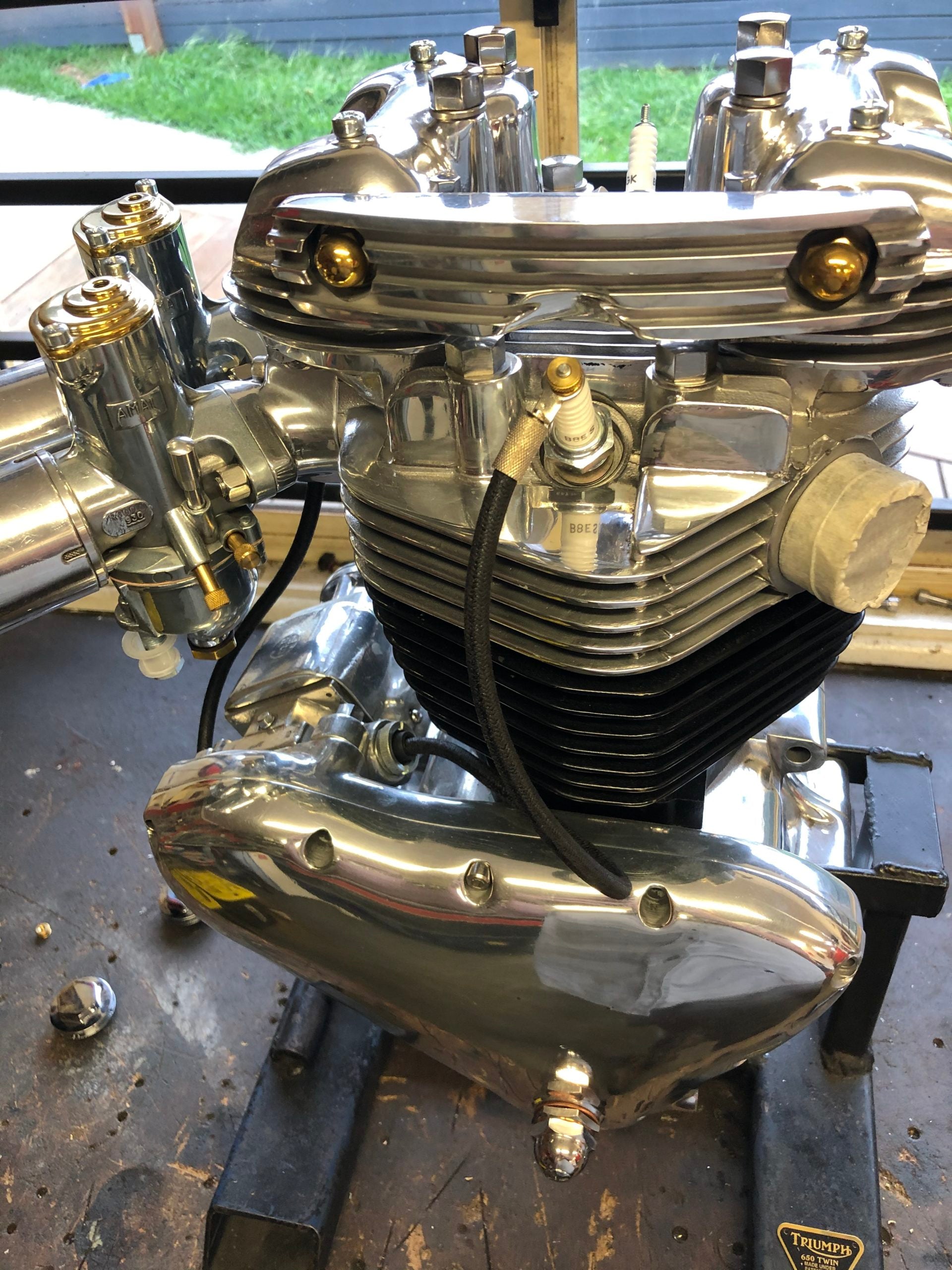

Vapour blasting or cleaning: This isn’t strictly necessary, however on the bikes we build, it’s usually specified we want the engine looking like new and running like new. Vapour blasting is the best way to achieve that fresh from the factory look on your engine cases. $500-1000

Crank rebuild/Balancing: This is dependent on the crank type this can be a very simple task, or a specialist task that requires the crank to be sent to a specialist. In the case of it being a simple task the cost is included in the parts/labour. If it needs to be sent away to be pressed apart, new bearings and balanced in the past it has cost me between: $800-1200

Labour: Assuming you have pulled the engine out of the bike yourself and you will re-install it again. Generally, the tear down and inspection will take 2-3 hours, this is where we run a few tests before tear down like a compression or leak down test, make sure the bike is running through the gears properly etc. Then we pull it down for inspection, either just the top end to do the valves and piston or the bottom end as well to inspect and rebuild the gearbox and crank. Once that is done we can catalogue the parts and work needed and provide a reasonably accurate price on the parts and machining.

With that done, parts are ordered, blasting done and machining completed before re-assembly. That usually takes between 6-10 hours depending. Assuming you’re paying $100/hr to the mechanic the total labour cost will be: $800-1300

With that information and guidance on the different costs involved we can talk about a few different things that can effect motorcycle engine rebuild cost.

-

DOME 3 IN 1 LED INDICATORS BLACK - PURPOSE BUILT MOTO

Regular price From $120.00Regular price$115.00Sale price From $120.00 -

HOLLOW TIP X 3 IN 1 LED INDICATORS BLACK - PURPOSE BUILT MOTO

Regular price From $120.00Regular price$115.00Sale price From $120.00 -

Brake / Tail Splitter

Regular price $8.00Regular price$8.00Sale price $8.00 -

Motorcycle Plate Light

Regular price $25.00Regular price$25.00Sale price $25.00

Variables that effect the cost of your engine rebuild.

There are a few different things that can greatly affect the costs involved with rebuilding a motorcycle engine. These can include:

- Bottom end condition: If your motorcycle has been tested and needs a rebuild but the bottom end and gearbox seems to function fine with no noise or evidence of wear a lot of people choose to rebuild the Top End only. This can essentially cut your costs in half.

- Internal damage or worn parts: If your motorcycle has any major components damaged this can quickly increase the cost of your rebuild. Needing to replace gearbox components, casings, cam shafts can get expensive very quickly. The ideal situation is opening the engine up and finding the only parts that need replacing are the pistons, conrods and some machining on the barrel.

- Availability of parts: Some bike models can be extremely hard to find parts for. Boutique brands, unpopular or short run models, or just very old models can be very difficult and in turn expensive to source parts for. We’ve become really good over the years at hunting down hard to find parts, but finding them is only half the battle. If they’re hard to find, they are always expensive.

- Extra machining: If your engine or cases have spun bearings, damaged bearing surfaces or Cam journals this extra machining can also increase the cost of your rebuild. In some cases, purchasing a good second hand case or head block can be cheaper than the repair machining needed.

How much does a motorcycle engine rebuild cost?

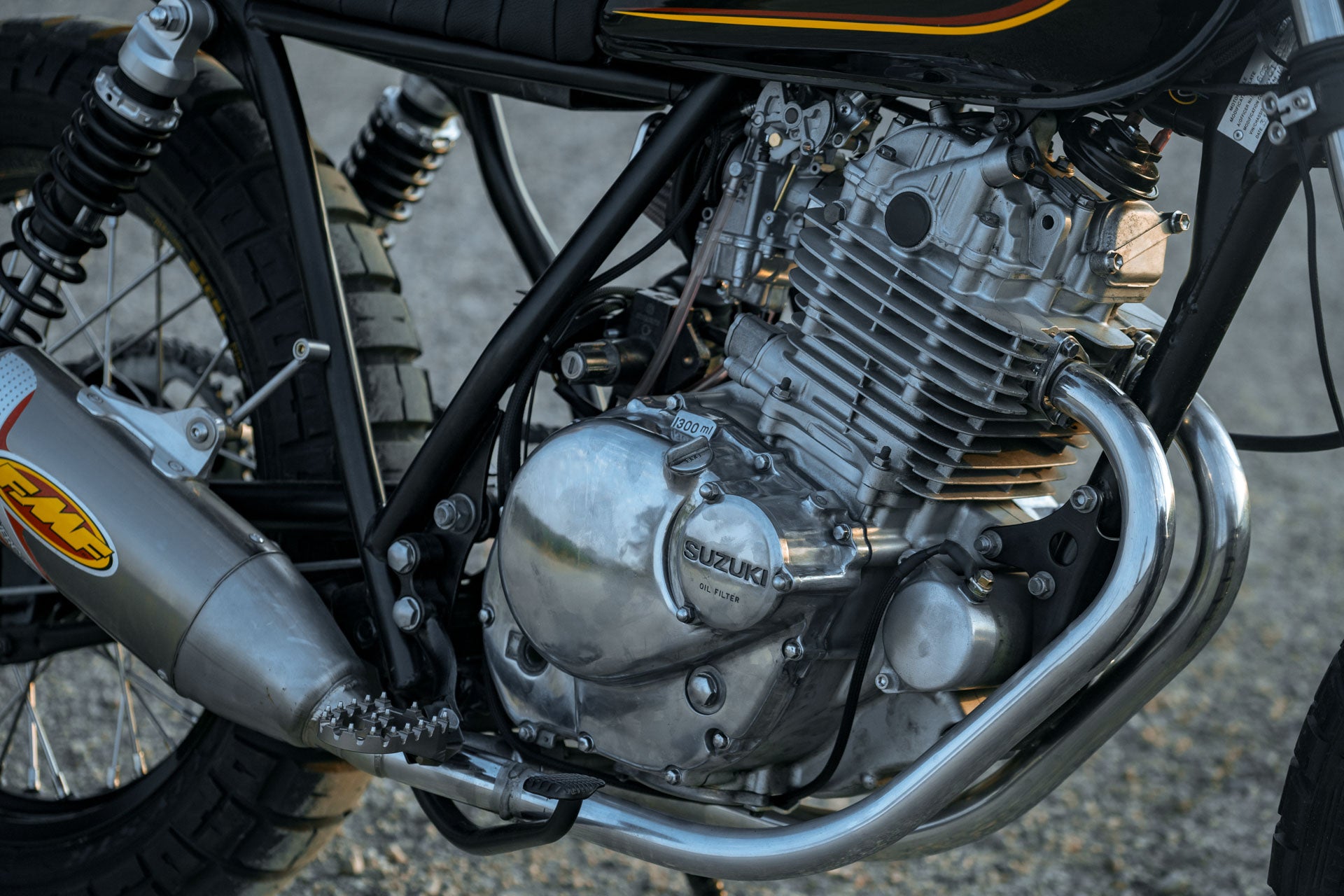

The best way to break this down is by Engine Type, as a general guide and taking into account the replacement of the usual wearing parts without allowing for any internal damage or replacement of non-standard rebuild parts. These numbers are based on the 70’s and 80’s model engines we usually rebuild. Modern bikes can be easier and cheaper to find parts for. As described above a number of factors can change these numbers but this is a good guide to base your expectations on.

Single Cylinder

Parts/machining: $1000-1500

Blasting/polishing: $800

Labour: $1000

Twin Cylinder:

Parts/machining: $1400-2000

Blasting/polishing: $800

Labour: $1200-1600

Four Cylinder:

Parts/machining: $1500-2200

Blasting/polishing: $1000

Labour: $1600-2000

Ways to save money on your engine rebuild

There are a few ways to lower your motorcycle engine rebuild cost. The most important would be proper maintenance and regular oil changes. If there’s a problem, inspect it and repair it early to avoid larger failures. A few other ways to lower the costs of your rebuild are:

- Don’t hydro blast the engine and clean the cases yourself. This can be done by hand, it takes a lot of time but can save you a good bit of cash. Especially if you want to paint your engine and don’t want or need that bright metal finish.

- Re-using some appropriate parts. Some parts that will often be replaced with new can be reused. If this is the case we will usually measure the parts for spec, inspect for wear and damage then assess whether they can be reused. This can be handy if parts simply aren’t available or are becoming overly expensive.

- Performing a top end rebuild only. As mentioned above this can cut costs on your rebuild by quite a lot. But you do take the risk of not inspecting the bottom end properly and having troubles down the line.

Performance upgrades you can do during an engine rebuild that lower engine rebuild costs

It’s part of our motorcycling nature that we want things to be better, faster and stronger. So what can you do to your old motorcycle engine during a rebuild to get better performance and reliability out of it?

We often rebuild old bikes, and are tasked with making them better than new. In our experience there are a few must haves when repairing your motorcycle.

Model specific upgrades: Some bikes are born with problems, a bit of research on your specific model bike can give you a really good idea on common problems and fixes for your bike. This could be anything from oil cooling journals getting blocked or a weak spring mount that can crack. Making sure we find those common issues and address them before they become a problem.

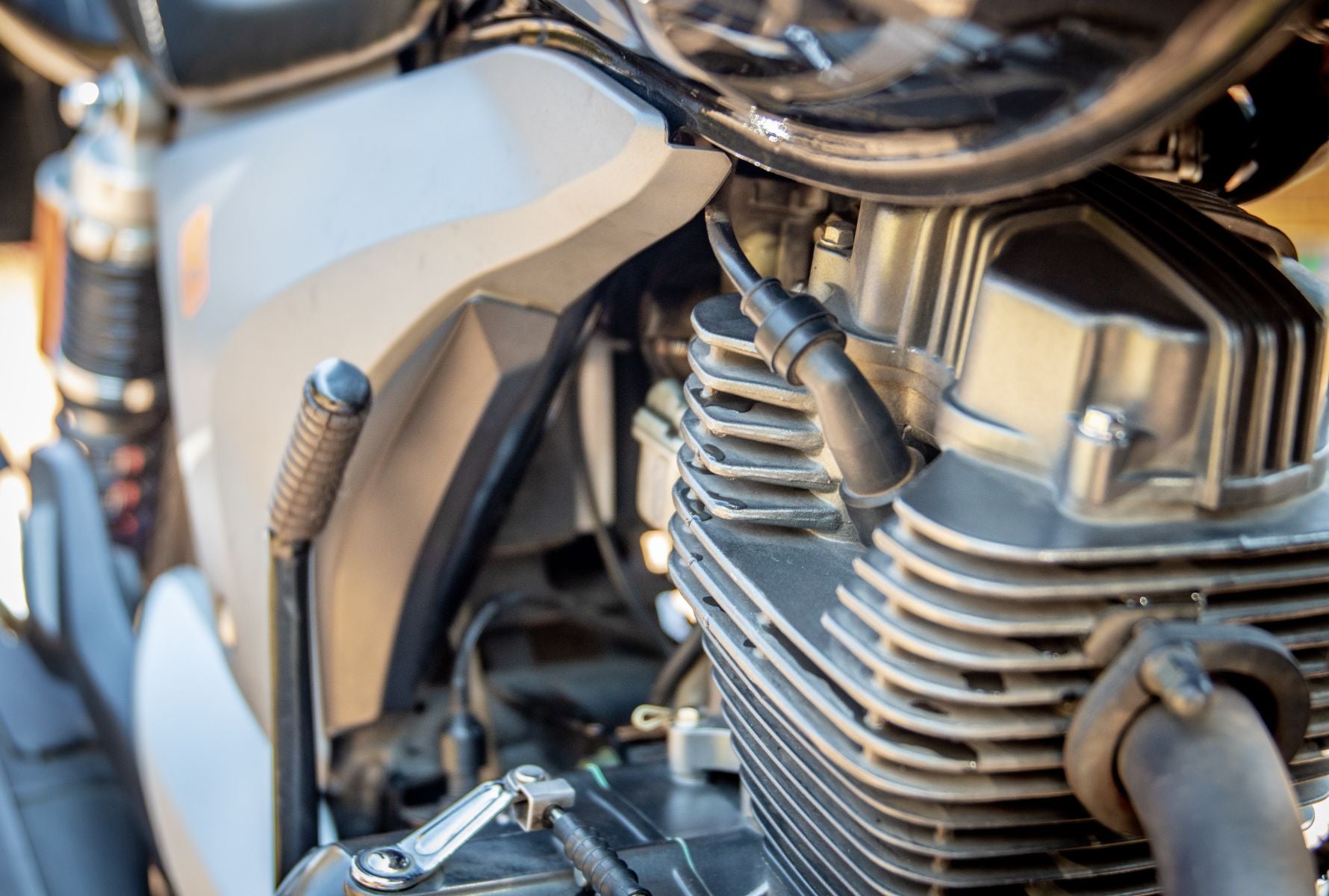

Ignition upgrade: We do this on 90% of our rebuilds- removing the old points ignition and replacing it with a digital ignition and advance unit. This paired with a set of performance coils can make a huge difference to your bike’s reliability. Some new bikes won’t need it but we’ve found it to be a really worthwhile upgrade on a lot of our projects.

Porting work: Another reasonably inexpensive upgrade is having some porting work done on your head. This increases Intake and exhaust flow through your engine by making the passageways bigger, and removing the rough surfaces from casting. The work done here doesn’t require any other upgrades, but for best results pairing with a carb upgrade and better flowing exhaust before a tune will generally reap better power output.

High Compression, performance or big bore pistons: When rebuilding usually you’re going to replace the piston anyway, most of the time for a few extra dollars you can upgrade to an aftermarket performance piston or even increase the capacity of your engine. The machining may cost a little extra but it’s a good way to get more power out of your machine. Some engines can be greatly increased in size and power very simply while others may need specialist work to be done.

Oversized valves: This one too requires some careful measurement and machining, but if done correctly can be a great increase of power to your bike. Far less common than a big bore kit, usually you will need to do the measurement and hunt around for parts for that specific model. Again, this upgrade increases power by letting the intake and exhaust gases flow faster than the factory set up.

Performance Cams: A cam is a component in the head of your motorcycle that opens and closes the intake and exhaust valves. Performance cams will change the timing, lift height and duration that the valve is open and closed for again aimed at allowing better flow through the engine to increase power on a certain curve. Different cams are manufactured for different performance characteristics so just make sure you choose the one that best suits your application. These will often need to be paired with new or upgraded valve springs.

There is a huge list of other upgrades that you can do from performance spark plugs, right up to a supercharger listed above though are the ones we see and do most often.

Before we wrap up we’ll give you a tip, when looking into your motorcycle engine it helps to know the ins and outs of your specific bike, we use ManualsLib to find all our motorcycle manuals so check those out to arm yourself with as much info about your bike as you can.

With your head stuffed full of knowledge, I’m pretty confident now you’ll have a good idea what you’re in for when it comes to your motorcycle engine rebuild cost. As mentioned this is about as accurate a guide as I can give you unless looking at your specific motor on my workbench. Make sure you get in touch with us if you’re in need of some PBM love on your motor.

WE BUILD BIKES WITH PURPOSE.

Purpose Built Moto is home for unique custom motorcycle builds. We offer a unique motorcycle customizing experience in the heart of the Gold Coast.

6 comments

You can check out this article for a guide on general pricing.

If you want a more detailed price we need to strip you engine down and inspect it.

Hi. My 2005 Yamaha 110A classic engine looks like it may be at the end of life. Compression in the front cylinder is 140lb and the rear is 110lb. The hard facing is worn off the rear cylinder tappets. What would an approx rebuild cost. It has a new starter clutch and new main clutch so it will just be the main engine.

Hey Tim,

I would say most Evo motors would fit into your frame, the capacity or performance would be determined on just how much you want to spend on doing it.

Are you local to the gold coast?

I have a 1987 ultra classic dresser. I want to put a bigger engine on it. I am looking at these motors that are already built. How big of engine can I get already assembled the bolt to my motorcycle and what is a general cost I don’t want to have to rewire the bike or put a elc brain on it

I can make out a great deal of essential information.

Great info, thanks for sharing