The Final steps are always the most exciting, The Scrambler is taking shape and you can start throwing sneaky pics to the lads making them jealous. Trying to convince them to join you on your greasy knuckle quest of bikedom. If you missed the first parts in the build series, view them here.

Time to bust open the wallet, blow the cobwebs out and start making a list of excuses to tell your significant other of where those savings are going, trust me telling them its for their birthday present has limited legs. The closing stages are where a lot of professionals get involved for me, I can’t spray or upholster so I leave it up to those who can.

If you’re up for the task of DIY on these steps hats off to you!

5. It’s going to get shiny, don’t get distracted.

The Suzuki project was stripped for the final time, parts sent to paint and seat sent to the upholsterer.

Nick opted to paint the frame himself and give the engine a quick once over with some cleaning fluid. As I said in the beginning he didn’t want anything too shiny and pretty on this bike. The color scheme I had in mind was reasonably simple. 1 main color- Gunmetal grey with 2 detail colors of deep cherry red and black, set out in a simple design.

On my builds thus far I always feel less is more, I stick to 2-3 colors and like to use raw metal finishes where I can. That said I still do love an outlandish Airbrush job on the right bike.

To match with the cherry red details we had, I scoured the earth for a nice leather, I landed on a great Tannery in the UK that specializes in Antique colors and found exactly what I wanted. I will admit I knew nick was a little worried when I mentioned a red seat but when he saw what I was talking about he came around pretty quick.

With the brushed stainless steel parts we fabricated there wasn’t a whole lot to the paint and leather for this bike which made it all relatively cheap. Before sending it in for paint and leather I will think about the paint design and settle on what I want, roughly mask out the design on the tank and fenders and mark the colors, same goes with the seat, It takes the guess work out of it.

6. Final Assembly

At this point in time I was so busy with other work I had to get nick to build the roller in his own garage, once the dust settled we wheeled it back up on the table and set to work with finishing his ride off.

First was new chain and sprockets followed by mounting the rear fairings, Brake calipers, headlight plate, and protaper handlebars.

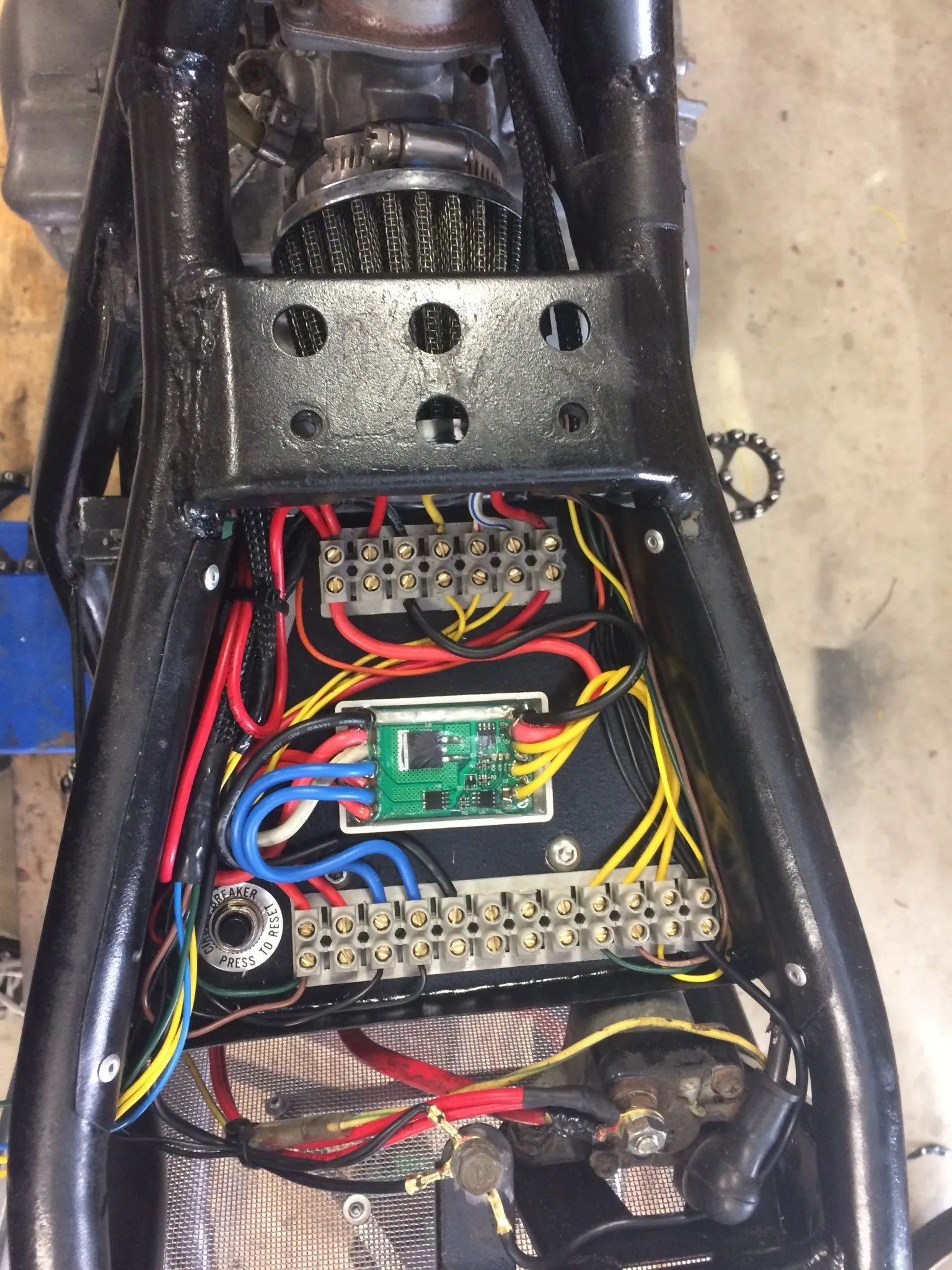

I folded up a quick electrics tray for under the seat and we went to work mounting all the lights and switches we needed to complete the wiring. Everything from indicators to your starter button everything went on there. This allows you to have an idea of what needs to be wired where and minimizes the chance of you missing something. With an original wiring diagram in hand and our new modified wiring diagram on the go I set out on the electrics. A detailed run down on your bikes electrics can be found here, complete with wiring diagrams.

Motorcycle Electrics 101- re-wiring your project bike.

For now let’s say we utilized the purpose built moto slim push button switches and silver anodized dome indicators along with a killer after hours choppers brake light and the custom built scrambler light plate. The wiring was hidden in the handlebars with the rest ran in some black snake skin to make it as discreet as possible.

Another Trick bit I prototyped for nicks build is a high rise muffler, raw welded with a brushed stainless finish. Used in conjunction with his standard headers and some of that good ol’ black heat wrap we all seem to love!

Once bolted together we ran the bike to make sure nothing was awry before putting the tank and final fairings on, followed by the standard top to toe check with my trusty torque wrench.

During this last process nick was getting more and more itchy to get this little bastard on the road, with every work session bringing us closer to getting some wind on his face.

That was it, bleed the brakes out and fire it! due to the upgraded exhaust and pod filter it would only run on choke, I pulled that carby and jumped from a 130 main to a 150, leaned the air slightly and she was running like a champ.

7. Ride out!

The Bike was done, the last bit to be bolted on was the seat. We were standing in the garage, kinda looked at each other and I said “that’s it mate, lets ride it!”

I could tell Nick was 50/50 nervous/excited, He blasted up and down the street a few times before we loaded it up on the ute (pick up for the our non-aussie friends) and headed for some trails. We spent months building a scrambler and it would be wrong to baptize it on the street. We hit some local dirt tracks and within minutes that damn thing was covered top to tail in dirt, perfect!

The raised stance gave a good high seated position although the rear suspension was a little stiff. The front was perfect and the re-purposed Pro-taper high rise mini bike bars handed out ultimate control for throwing it around some sharp corners and letting the rear wheel trail out under power. Then there was the sound, the new muffler we designed and used on the GN250 sounded beastly, it definetly lets you know its there without being obnoxiously loud. All this left me with one thought, ‘I need a scrambler…’

I hope you got some good insight into the process that bought his little ripper to be.

Please leave a comment below and sign up to our newsletter for more builds and exclusive content.

Thanks for taking the time.

Check out the full gallery here

Tom

WE BUILD BIKES WITH PURPOSE.

Purpose Built Moto is home for unique custom motorcycle builds. We offer a unique motorcycle customizing experience in the heart of the Gold Coast.

9 条评论

The best thing to do on these bikes is a carburettor and exhaust upgrade, paired with a bit of porting work to the head and a performance coil.

Further than that you can go deeper with High Comp pistons etc but the differences in power vs cost aren’t as good.

Hi

Did you do any work on the engine to increase power? If so I would be very interested.

Thx,,

OK, so I shouldn’t worry that swingarm rises the chain, just use sturdier slider.

Thanks a lot!

If you use the right material a chain slider will be all you need.

We use a HDPE plastic to make ours.

Hi Tom,

I started my GN250 project, and I won’t lie: it is very much inspired by your work.Although I stumbled upon a problem: after fitting longer rear shocks chain is severly grinding against swingarm. I fabricated a chain slider, but it won’t probably last long, since highest point of swingarm is higher than highest point of front sprocket.

How did you dealt with chain in your projects?

Hi Adam,

The Shocks are 420mm long from memory. long time ago now. A shorter wheel base will only come into play at high speed (GN250 tops out at 100kph)

How long are those rear shocks? Do they have any extra travel, since it’s a scrambler?

Doen’t shorter wheelbase affect negatively steering?

Thanks for infrmation.