Installing rearsets on a CX500 Café Racer

Rearsets are a staple modification for anyone serious about making their café racer or brat build function properly. When moving the bars down to clip ons, the standard foot peg position will generally have you folded over like a half opened pocket knife. Shifting the foot position back results in better ergonomics for the rider.

Doing this modification is usually pretty straight forward and involves nothing more than fabricating a new peg mount and making the shift and brake linkage arms longer. Then you get anomalies like the fucking CX500 which because of the orientation of the gearbox/engine, needs some wizardry with a sprinkling of bullshit to make it work. It’s a long process when you’re first figuring it out, so this article will guide you through my solution, and hopefully help you along the way with yours.

You will need to be able to weld, and either own a lathe or have a mate with one. Lets go through what you’re going to need to mount these rearsets on your CX500.

Tools you need:

- General hand tools

- Grinder

- Electric drill

- TIG or MIG welder

- Lathe

Materials to do the job:

- 4 x 6mm eye bar ends

- 14mm round bar stock

- 20mm round bar stock

- 12mm Aluminium rod 200mm

- M6 + M8 Fasteners

- 6mm Mild steel plate 40mm x 50mm

Before we get going on the gear shift, I’ll mention the rear brake. On the Signature series CX500 I used a linkage mechanism to operate the rear drum, on this build I’m using a cable operated conversion that will be a little simpler to make and hopefully a little easier.

The basis of this whole exercise is transferring movement from forward/backward to up/down. The CX500 needs to have this shift in movement to suit the gearbox configuration.

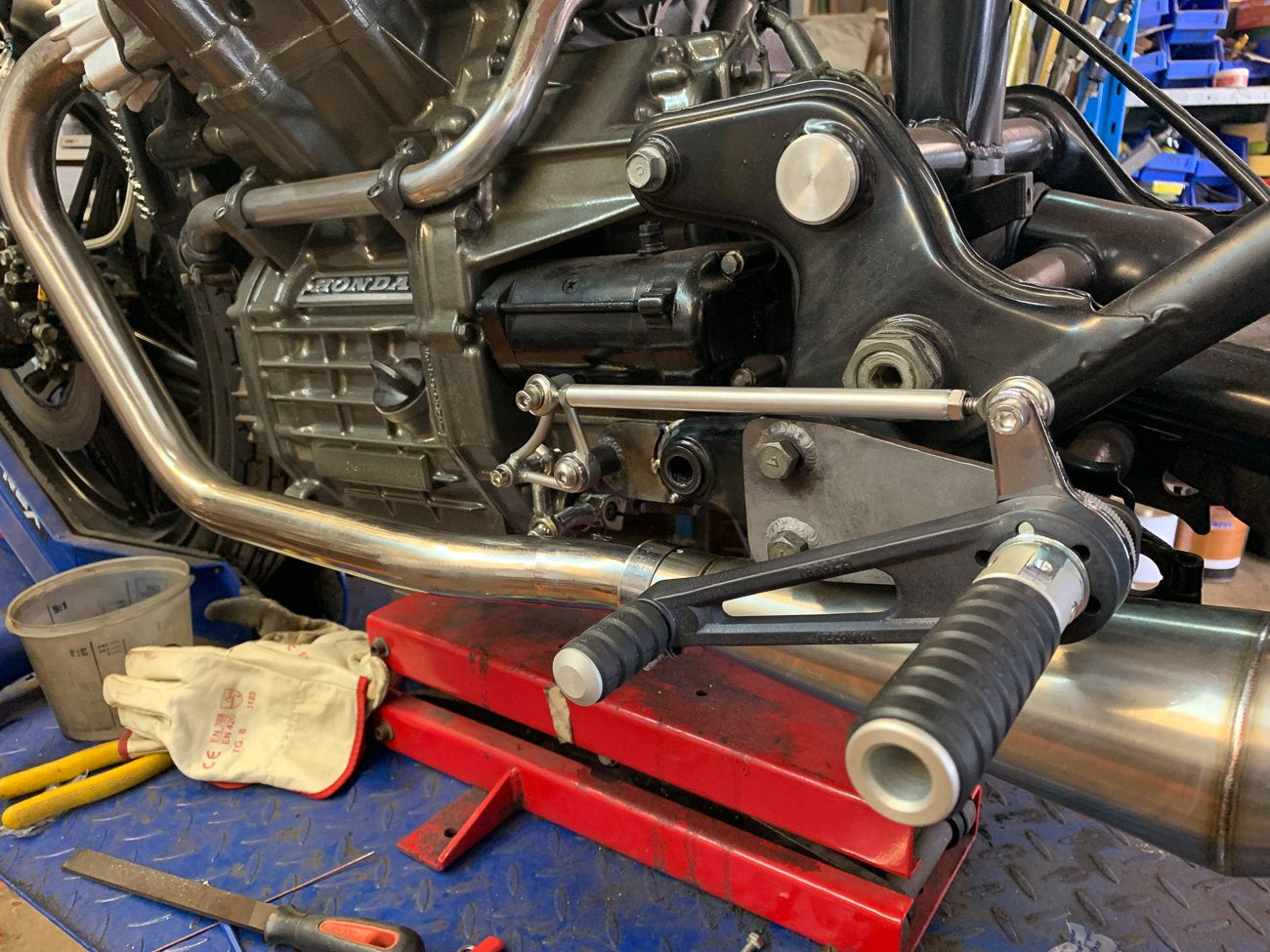

This blog will cover the linkages and how to make them, the position of the rearsets I’ll leave up to you. There is a few ways to do it, and a multitude of different positions to place them. On this build, with a brat seat and clip ons, I’ve gone with a lower set foot peg that’s mounted 70mm rear of the swing arm pivot. I’ve used Tarrozzi universal rearsets and welded in a threaded bung to the unused footpeg post hole.

Once you’ve got your footpegs mounted up, lets take a look at linking that to the Shift spigot.

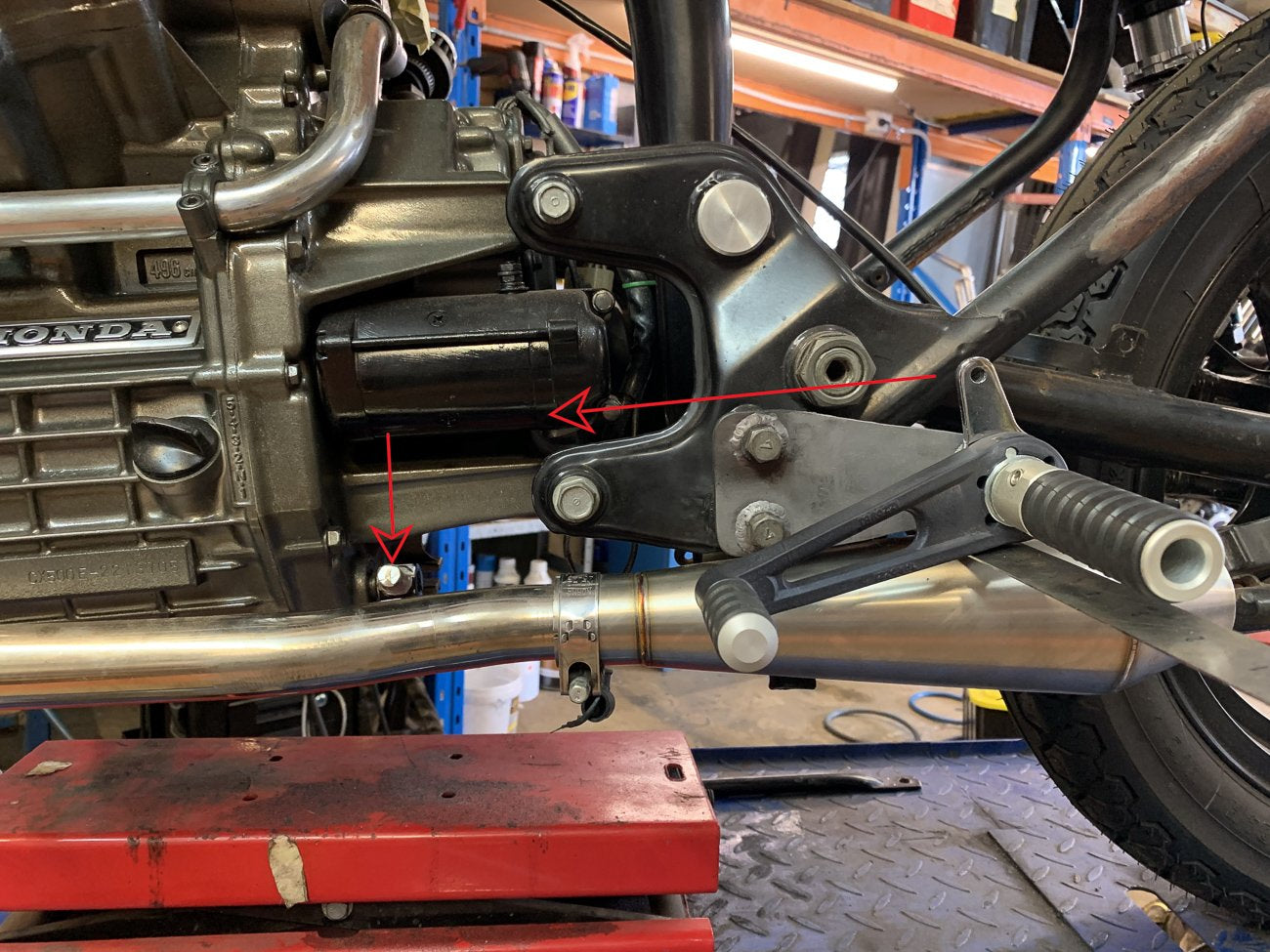

Cut your factory shift lever off leaving a little tab to weld to later. Now I need to make a mount point for the 90 deg linkage arm. In the past I’ve tapped a small hole in the head of the mount bolt, this way made it a little difficult to then reach forward again to the shift spigot.

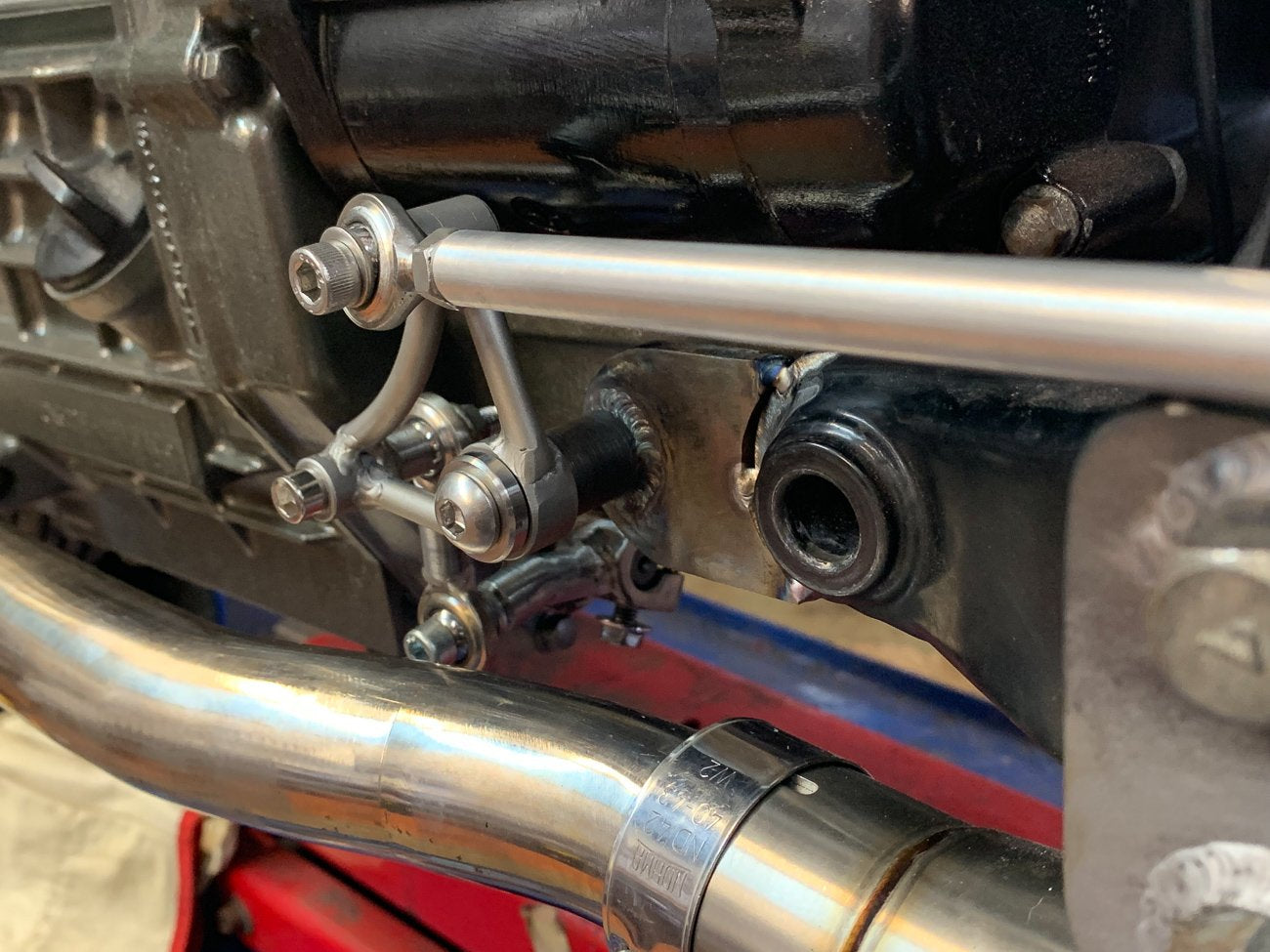

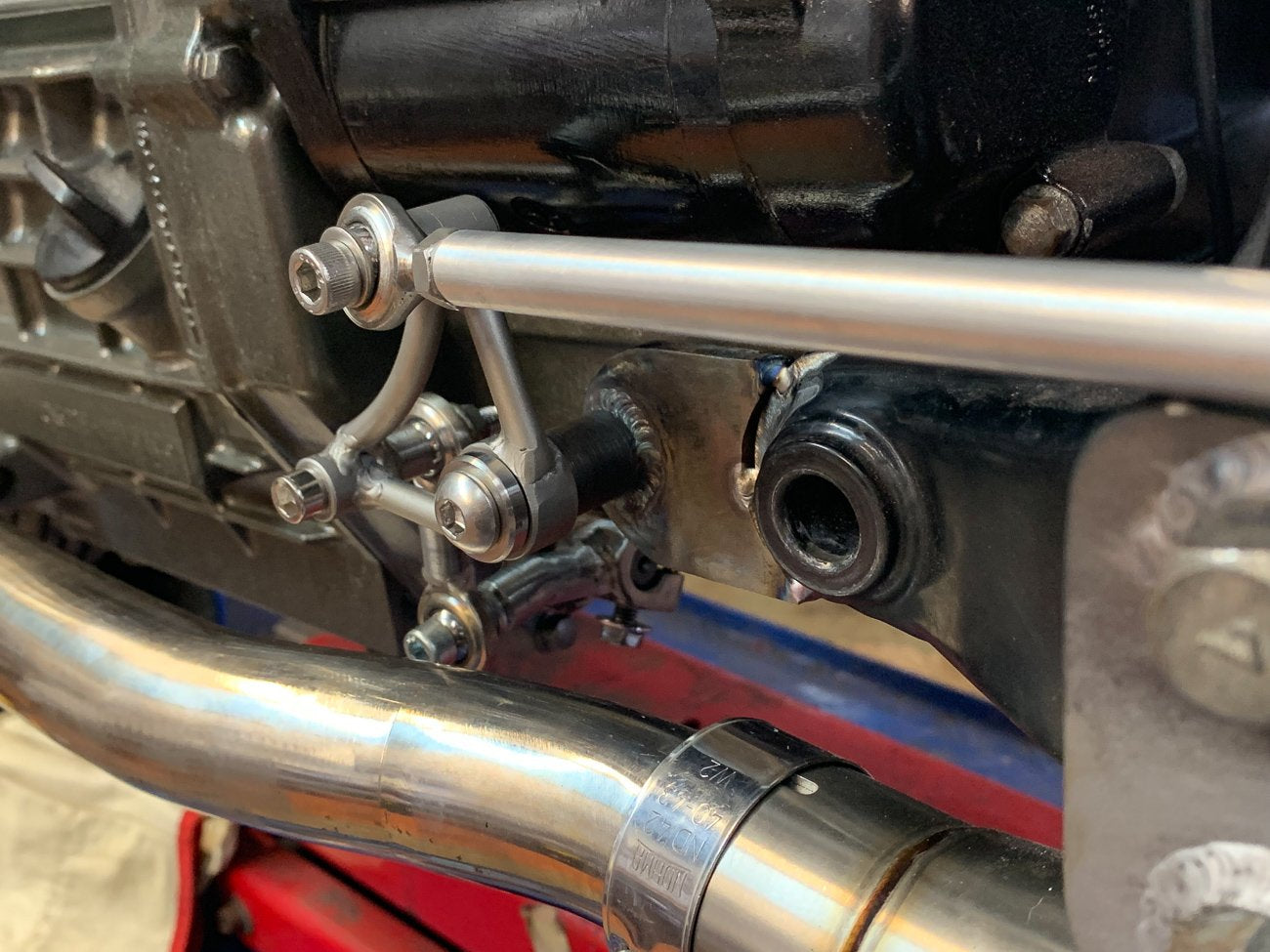

The method used here is a lot easier and has it lining up perfectly. I cut a piece of flat plate 40mm x 50mm and radius both ends as shown. One end gets welded to the frame, the other is just rounded to look nice.

From the measurements I took if you go much longer than 50mm on this mounting piece it may get in the way when trying to remove the motor from the frame, play it safe and stick to 50mm.

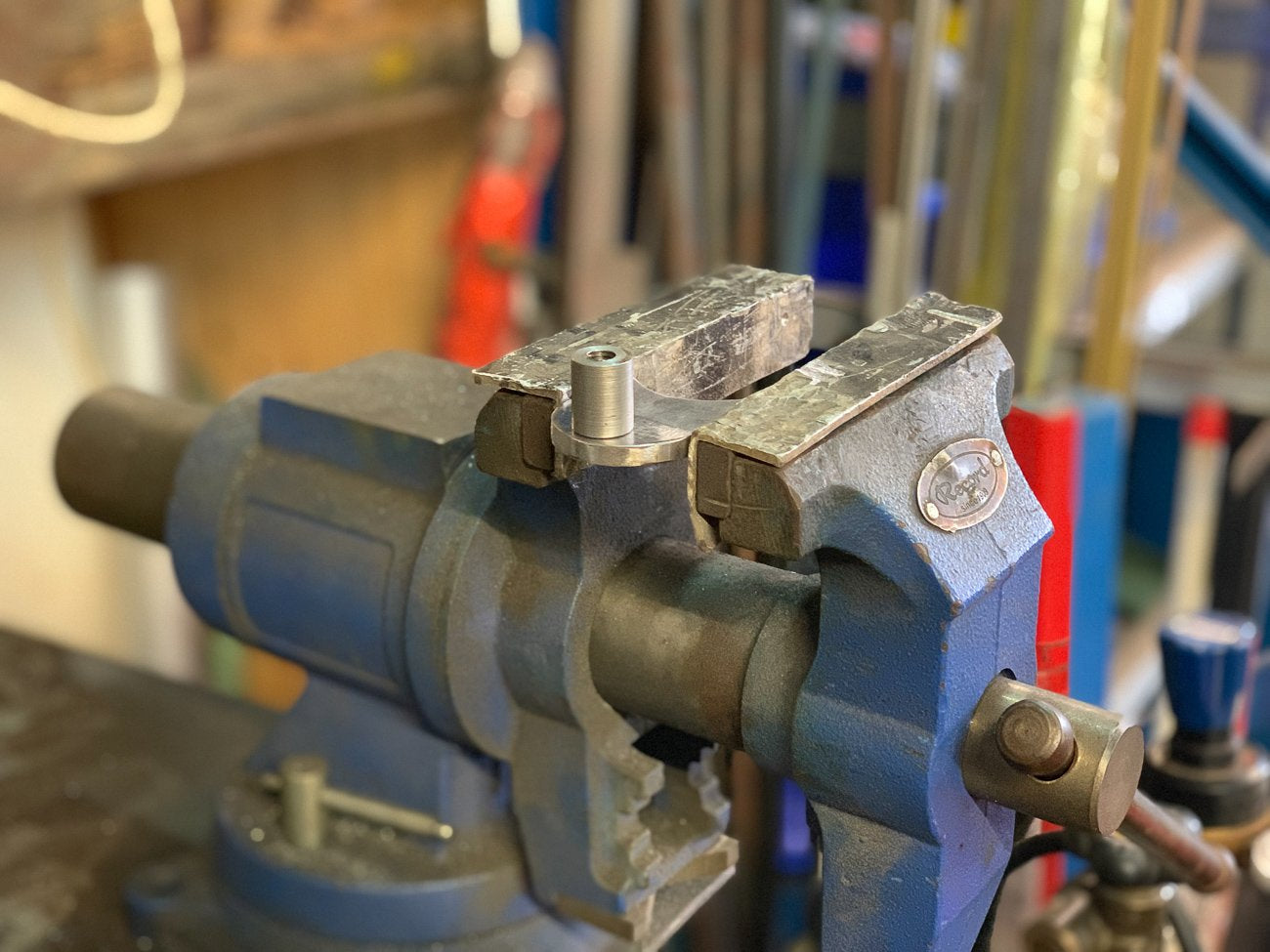

Once that’s cut and smoothed out I’ll make a 20mm offset threaded bung to weld onto the plate. 14mm OD with an M8 thread in it.

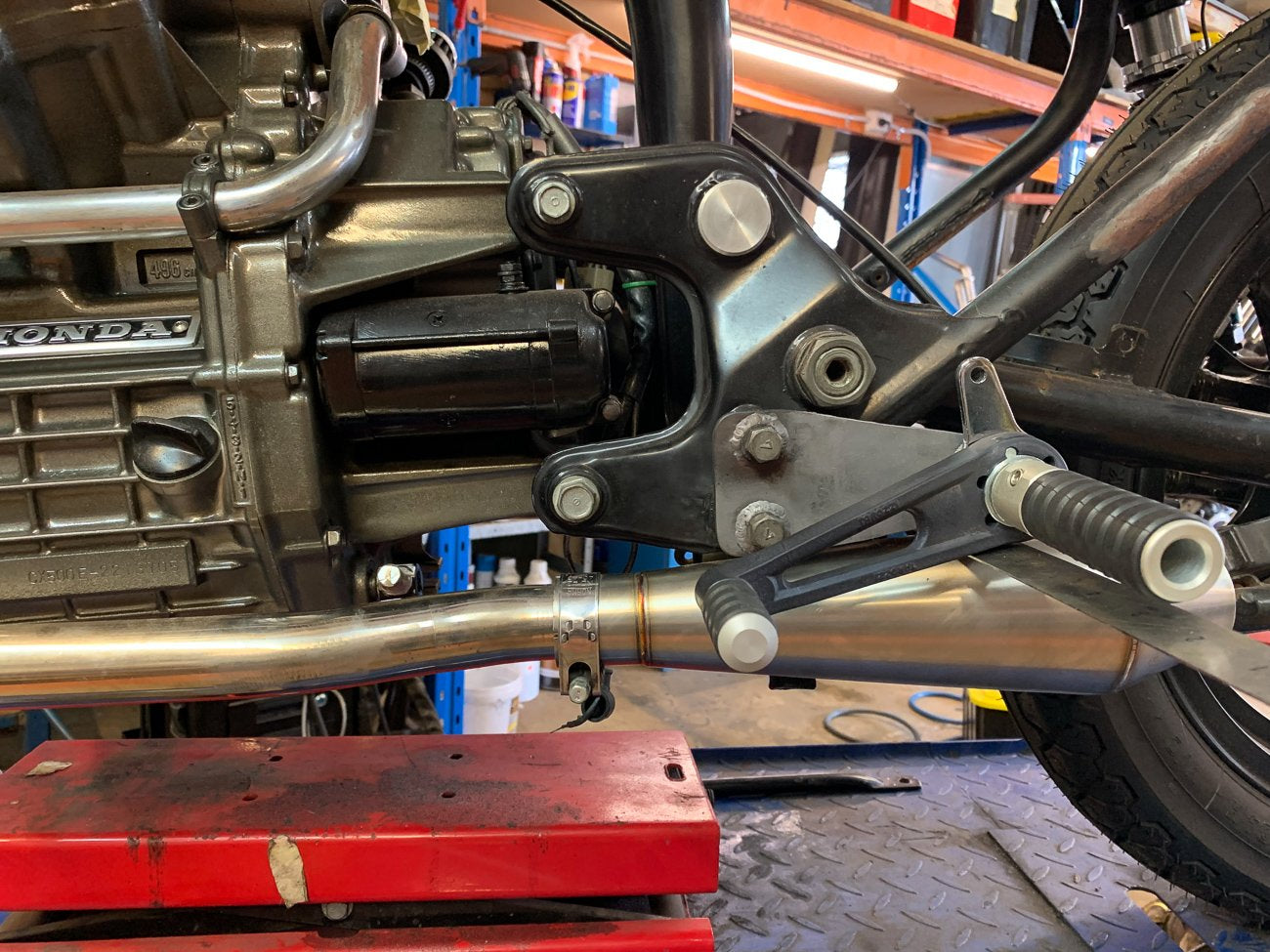

Weld that to the center of the flat plate the remove the paint front the Lower engine bolt mount section of the frame. I’ve just tacked this up here because Ive yet to drop the engine out, when I do I’ll finish weld it properly.

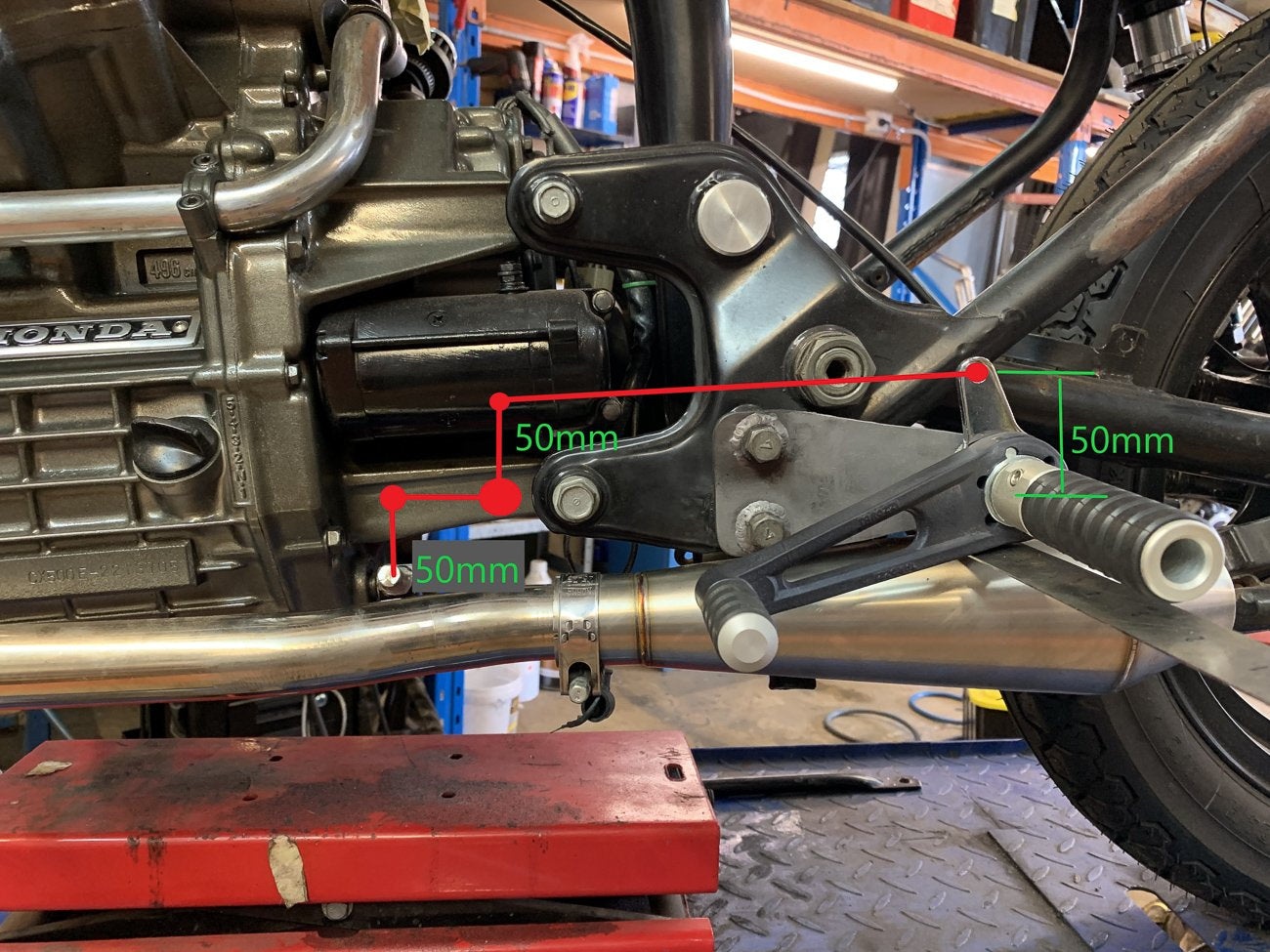

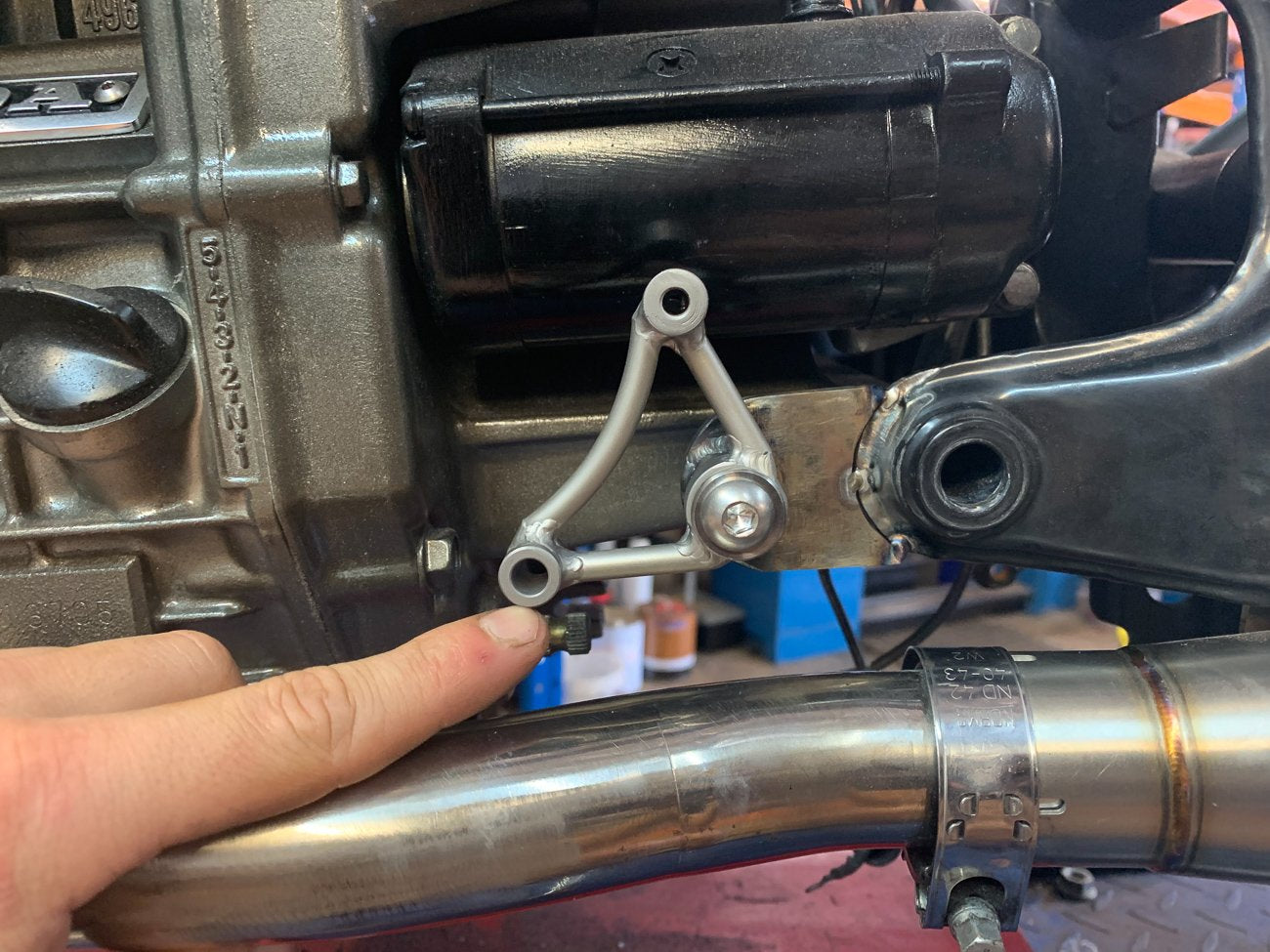

Time to fabricate the 90 deg arm for this CX500 rearset peg. Its important to note that if you make these arms to short or long, or make them un-even it can effect the way your foot shift operates and feels. Either moving too far to shift the gear or moving only slightly. To keep the ratios to same, I measure the distance from the center of the pivot point on the footpeg to the center of the linkage bolt hole. It’s 50mm, so the 90 Deg linkage arm will also be 50mm on each side.

I decided to make this linkage arm a bit of a feature, you may choose to make it a little less pretty. As long as it works who am I to judge, do what you want. For this youll need:

1x central pivot point, 12mm hole

1 x pivot bushing, 8mm hole

1 x linkage arm mounts, 6mm hole

1 x linkage arm mounts, 6mm thread

On the pivot point I’ve turned down a bit of stainless steel 20mm OD with a 13mm hole, then made a pivot bushing 13mm OD with an 8mm hole and a step on the top to hold the pivot point in place. The measurements aren’t critical but the fit is, make sure they can move freely when together and have minimal movement side to side. The 2 linkage mount points are 10mm OD one with a 6mm Hole, the other with a 6mm thread aprrox 15mm high.

Mark on a bench the centre point, and measure 50mm either side at a 90 deg angle, then set the pivot point and 2 linkage mounts on the mark, and link them up. I’ve used some stainless steel 6mm rod that I had and shaped it up so it looks pretty. Do it how you like.

Once the 90 deg arm is finished, mount it up and you’re ready to link it to the gearbox. With the 90 deg arm in place and the shifter fitting mounted I took some measurements to extend the shift fitting.

I welded a short 12mm round bar onto the factory shifter fitting that I could then tap a 6mm thread into. Once that’s done its just a matter of making a small linkage arm using 2 of the 6mm eye bar ends and a short 30mm extension piece. This can be welded up as the adjustment will be gained in the second linkage rod.

The eye bar ends are critical here to allow movement. The shifter pivots to operate, which means it operates on a radius. Moving up and down in a circular motion. If you directly link the shifter to the arm it will lock up and not move.

Mock up the shift linkage and set the footpeg at the angle you want it you can now measure and fabricate the final linkage arm using the 2 remaining 6mm eye bar ends, cut the aluminium rod to length, tap the threads in each and screw the bar ends in with a lock nut on each end. You can then adjust the length to perfectly suit your foot position. Once that’s in place, you can sit back and survey all that you have accomplished on your new CX500 rearsets.

I’d also recommend at this point to sit on the bike make some engine noises with your mouth and test that the shift linkage operates as it should. If that works, you’ve done it right!

When I made my first rearset there was no info out there to help me, I had to sit down and spend hours and hours figuring it all out. I’m thankful for that thought exercise, but if you need help, its now here for you. As with all things, make it your own and have fun doing it.

If you liked the article, please share it with your mates, leave me a comment or subscribe to our newsletter to make sure you never miss a custom bike release or a helpful article like this one.

WE BUILD BIKES WITH PURPOSE.

Purpose Built Moto is home for unique custom motorcycle builds. We offer a unique motorcycle customizing experience in the heart of the Gold Coast.

Комментариев: 12

Slipstream Cycle Works builds a bolt-on kit for the CX. Simple as lace them up and ride.

Hey ANthony,

The brake on this particular bike was swapped to a cable set up.

The rest of the info is on the build blof for the signature series bike.

How did you tackle the raer brake linkage? What hand levers are they on your signature cx build, and have you eliminated the clutch safety solenoid, if so any info is much appreciated, love the gear lever linkage set up mate, great job

Mock up the shift linkage and set the footpeg at the angle you want it you can now measure and fabricate the final linkage arm using the 2 remaining 6mm eye bar ends.

This is an excellent piece of writing! I am looking forward to reading a new custom bike release or a very helpful article like this one!